D540 and D545 DO Sensors

Models D540 and D545

OxyProbe DO Sensor

After

several years of refinement we are introducing our latest set of improvements

all bundled up in one new sensor, the OxyProbe? II.

The new

membrane design is modeled after our successful 25 mm membrane cartridge. It has

an expandable inner Silicone bladder that holds the electrolyte within a 316L

stainless steel cage. During SIP processes or during autoclaving the electrolyte

turns to steam, but does not distend the measurement membrane because the

internal bladder expands first, taking the pressure off the sensitive

measurement area. This allows us to have a maximum of electrolyte present, with

minimum risk of damage to the sensor. The new membrane cartridge design is easy to use

and durable enough to be used many times over if necessary.

REPLACEMENT PARTS

O-rings: AG-SR15

Membrane Cartridges: Single, Four and 16 piece Cartridge

Kits

Choice

of Industry Standard 4-Pin Connector or VarioPin

Our standard D9 connector

has hermetically sealed gold-plated contacts in a glass insulator that offers

the ultimate in signal isolation and transmission. For customers with installed

VarioPin cable systems we also offer the VP connector as a standard option on

all of our designs.

Hygienic Sensor

Design:

•

Microrganisms cannot adhere to the sensor surface due to the enhanced finish

(N5/Ra15μ in Quality).

• The sensor is fully sterilizable

and autoclavable.

Time-Saving

Maintenance:

•

Membrane body and sensor inner body can be changed out very quickly. A simple

membrane body replacement takes just two minutes and can be made on site by the

user.

• Due to the

modular design, the different sensors have basically the same spare parts. This

minimizes inventory stocking requirements.

Features

Overview:

•

Autoclavable and steam sterilizable.

• Accurate measurement and quick

response.

• Long

lasting and easy to maintain membranes.

• FDA positive listed materials of

construction.

•

Hygienically polished N5 surface finish (Max. Ra15μ in).

• Wetted O-rings comply with FDA and

USP Class VI standards.

Other

Highlights:

• Comes

with either waterproof VarioPin or D9 connector.

• T-Pull connector versions allow

for easy removal from fermenter and reduces strain on cable.

• Variety of sensor lengths

available.

Replaceable Anode/Cathode

Assembly

A concept

pioneered by Broadley-James, this unique assembly permits the sensor to be

repaired quickly and reliably. Send your sensors to us for rebuild and save

about half the price of purchasing a complete new sensor assembly!

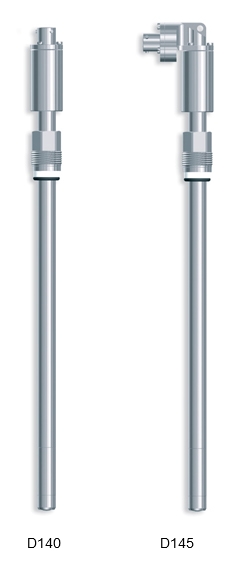

D140 and D145 DO Sensors

Models D140

and D145 OxyProbes

The OxyProbe 12 mm dissolved oxygen

sensor offers the most rugged and versatile design for benchtop vessels. The

compact profile saves space on a crowded headplate. It will fit directly into

any 12 mm multipurpose port with standard compression fittings or Pg13.5

threads. The small diameter facilitates DO measurement in small volumes,

especially bottles and spinner flasks.

The OxyProbe 12 mm DO sensor has the

same rugged performance as the 19 mm and 25 mm sensors. This polarographic

sensor utilizes the longer silver anode and small cathode which has become the

industry standard. It also uses the same semi-permeable, Silicon/Teflon

composite membrane, reinforced with stainless steel mesh.

All OxyProbe dissolved oxygen sensors

are available with a right angle connector. This low profile design

provides:

•

Protection against cable fatigue

• Improved grip for sensor

extraction

• Increased

clearance between vessels

• Reduced random sensor mobility on flat

surfaces (won’t roll off the table)

REPLACEMENT PARTS

Membrane Cartridges: Single, Four, and 25 piece Cartridge

Kits

SPECIFICATIONS

Features:

• 316L Stainless Steel

• Serialized for

traceability

• RA32

finish with electropolish on wetted parts

• Internal EPDM

o-rings

How to choose a

sensor:

(1)

Determine how far the sensor should project into the vessel.

(2) Decide whether a right

angle connector is preferred over a straight connector.

(3) Choose the correct cable

length and connector. All DO sensors require

cable and connector

assemblies.

It is important to regularly

maintain the sensors by inspecting and calibrating them. The membrane cartridge

should be checked and refilled prior to every use.